- August 14, 2024

- Posted by: wellcoindustries

- Category: Rebar

Introduction

The automotive industry is constantly evolving, with manufacturers seeking materials that offer better performance, durability, and efficiency. One such material making waves is fiberglass rebar, a lightweight and corrosion-resistant alternative to traditional steel rebar. While fiberglass rebar has been widely used in construction, its application in the automotive sector, particularly in car bumpers, is gaining traction. This article delves into the reasons why fiberglass rebar is becoming the go-to choice for car bumpers, highlighting its key benefits and the advantages it offers over conventional materials.

Understanding Fiberglass Rebar

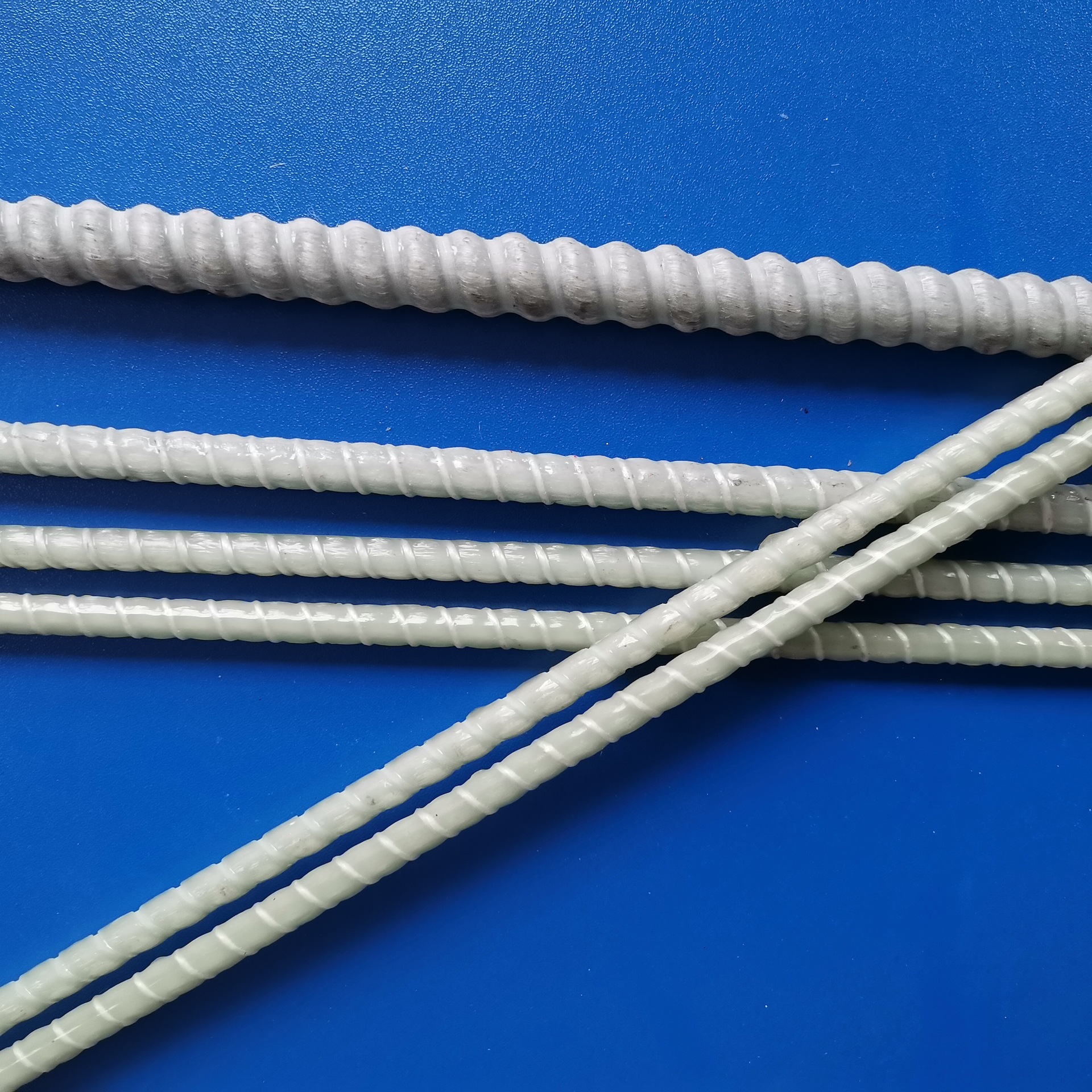

Fiberglass rebar, also known as glass fiber reinforced polymer (GFRP) rebar, is a composite material made from glass fibers embedded in a resin matrix. Unlike traditional steel rebar, which is prone to corrosion and heavy, fiberglass rebar is lightweight and resistant to corrosion. This makes it an ideal material for applications where weight reduction and longevity are critical, such as in the automotive industry.

When it comes to reinforcing structures like car bumpers, fiberglass rebar offers several advantages over steel. Its high tensile strength ensures that it can withstand significant impact, providing essential protection in the event of a collision. Additionally, the corrosion-resistant nature of fiberglass rebar means it maintains its integrity over time, even when exposed to harsh environmental conditions.

Advantages of Fiberglass Rebar for Car Bumpers

Fiberglass rebar’s unique properties make it particularly suited for use in car bumpers. Durability is one of the most critical factors in bumper design, as it directly impacts the vehicle’s ability to absorb and dissipate energy during a crash. Fiberglass rebar excels in this regard, offering high impact resistance that enhances the bumper’s protective qualities.

Another significant advantage is the material’s lightweight nature. By reducing the weight of the bumper, fiberglass rebar contributes to overall vehicle weight reduction, which in turn improves fuel efficiency. In an industry where every pound matters, this can lead to substantial cost savings over the vehicle’s lifetime.

Corrosion resistance is another compelling reason to choose fiberglass rebar. Unlike steel, which can rust and weaken over time, fiberglass rebar remains unaffected by moisture, chemicals, and other corrosive elements. This ensures that the bumper remains strong and reliable, even after years of exposure to challenging conditions.

Comparing Fiberglass Rebar with Other Materials

When comparing fiberglass rebar to traditional steel rebar and other potential materials, several factors come into play. Steel has long been the standard for reinforcement, but it comes with significant drawbacks, particularly in automotive applications. Its susceptibility to corrosion and its weight are major concerns, especially in environments where vehicles are exposed to salt, water, or chemicals.

Fiberglass rebar, on the other hand, is not only resistant to these elements but also offers a superior strength-to-weight ratio. This makes it a more efficient material for car bumpers, where minimizing weight without compromising strength is crucial. While the upfront cost of fiberglass rebar may be higher than steel, its long-term benefits—reduced maintenance, increased durability, and better performance—make it a cost-effective solution in the long run.

Conclusion

Fiberglass rebar is emerging as a superior alternative to traditional materials in the automotive industry, particularly for car bumpers. Its durability, lightweight nature, and resistance to corrosion make it an ideal choice for manufacturers looking to enhance vehicle performance and longevity. As the industry continues to evolve, innovative materials like fiberglass rebar will play an increasingly vital role in shaping the future of automotive design. If you’re considering upgrading your vehicle’s components, now is the time to explore the benefits of fiberglass rebar.