- September 25, 2024

- Posted by: wellcoindustries

- Category: Rebar

Introduction

Concrete reinforcement has traditionally relied on steel rebar to provide the necessary tensile strength and structural integrity. However, steel rebar, while effective, presents some drawbacks—most notably its susceptibility to corrosion, especially in environments with high moisture or chemical exposure. This has led to a growing need for more durable, corrosion-resistant alternatives in construction projects.

Enter fiberglass rebar mesh, a revolutionary material that is gaining popularity in the construction industry. Made from Glass Fiber Reinforced Polymer (GFRP), fiberglass rebar mesh is a non-corrosive, lightweight, and highly durable alternative to traditional steel rebar. It offers numerous advantages, including long-term durability, ease of installation, and lower maintenance costs, making it a game-changer in concrete reinforcement. In this article, we’ll explore the benefits, applications, and future potential of fiberglass rebar mesh in modern construction.

What is Fiberglass Rebar Mesh?

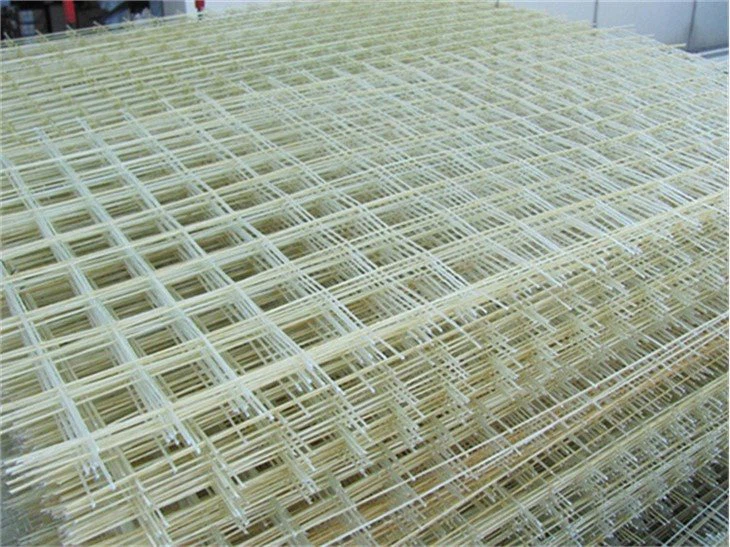

Fiberglass rebar mesh, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, is a composite material made from glass fibers and a polymer resin matrix. These fibers are carefully woven together to form a mesh that can be embedded in concrete to provide tensile strength, just like traditional steel rebar. However, the key difference lies in the material properties: fiberglass rebar mesh does not rust or corrode, making it an excellent solution for environments where steel rebar would typically degrade over time.

The manufacturing process involves combining glass fibers with a thermosetting resin, which is then cured to form a high-strength, lightweight material. The resulting product offers remarkable flexibility, tensile strength, and durability, which ensures that structures reinforced with fiberglass mesh can withstand the stresses imposed by daily use, weather conditions, and even chemical exposure. Its superior performance compared to steel rebar is making it an increasingly popular choice in a variety of construction applications.

Key Benefits of Fiberglass Rebar Mesh for Concrete Reinforcement

One of the most significant advantages of fiberglass rebar mesh is its resistance to corrosion. Unlike steel, which is prone to rusting when exposed to moisture and chemicals, fiberglass mesh remains unaffected by such environmental factors. This makes it a particularly valuable option for projects in coastal regions, marine structures, or areas with high levels of chemical exposure. Over time, this corrosion resistance can significantly reduce maintenance costs and extend the lifespan of reinforced structures.

In addition to its corrosion-resistant properties, fiberglass rebar mesh is much lighter than steel, which makes it easier to transport and install. This reduction in weight doesn’t come at the cost of strength, as fiberglass mesh has a high tensile strength that rivals, and in some cases exceeds, steel rebar. Its flexibility also makes it easier to shape and adapt to complex design requirements, providing construction teams with more versatility.

Another important factor is sustainability. As the construction industry shifts towards more eco-friendly practices, fiberglass rebar mesh presents an appealing solution. It requires less energy to produce compared to steel and has a longer lifespan, reducing the need for frequent replacements. In terms of cost-effectiveness, while fiberglass mesh might have a higher initial cost than traditional steel, its long-term benefits in terms of maintenance, durability, and environmental impact make it a more economical choice over the life of a project.

Applications of Fiberglass Rebar Mesh in Construction

Fiberglass rebar mesh is widely used in various construction applications, particularly in environments where the reinforcement material is exposed to harsh conditions. In infrastructure projects such as roads, bridges, and tunnels, fiberglass mesh is favored due to its high durability and corrosion resistance. It’s especially beneficial for marine projects—such as docks, piers, and seawalls—where exposure to saltwater accelerates the corrosion of steel.

Another significant area of application is in chemical-heavy industries, where exposure to corrosive materials could shorten the lifespan of traditional steel reinforcement. Fiberglass mesh for concrete is increasingly being used in the construction of industrial floors, storage tanks, and pipelines, where chemical resistance is critical for maintaining structural integrity.

Residential and commercial construction projects are also turning to fiberglass rebar mesh as a lightweight, durable solution for reinforcing concrete slabs, walls, and foundations. In fact, its flexibility makes it particularly suitable for complex architectural designs that require bending and shaping without compromising the structural strength of the material.

Fiberglass Rebar Mesh vs. Traditional Steel Rebar

While both fiberglass rebar mesh and steel rebar serve the same fundamental purpose of reinforcing concrete, they differ significantly in terms of performance, cost, and longevity. Steel rebar has long been the industry standard due to its strength and relatively low initial cost. However, the biggest disadvantage of steel is its tendency to corrode over time, especially in humid, salty, or chemical-rich environments.

In contrast, fiberglass rebar mesh is completely resistant to corrosion, which gives it a distinct advantage in such environments. While the upfront cost of fiberglass rebar is often higher than steel, the long-term savings in maintenance and the extended lifespan of the material often justify the investment. Additionally, fiberglass rebar is significantly lighter, which reduces transportation costs and simplifies the installation process, especially on large construction sites.

However, there are certain limitations to fiberglass rebar mesh. For example, while it performs well under tension, it may not be as effective in environments that require compressive strength. Furthermore, in projects where budgets are extremely tight, the initial cost of fiberglass may be a deterrent. Despite these limitations, for projects in corrosive or challenging environments, the benefits of fiberglass rebar mesh far outweigh its drawbacks.

Conclusion

As the construction industry continues to innovate and evolve, materials like fiberglass rebar mesh are playing a crucial role in shaping the future of concrete reinforcement. With its impressive corrosion resistance, lightweight structure, and long-term durability, fiberglass rebar mesh is an excellent alternative to traditional steel rebar, particularly in environments where steel would degrade over time.

For contractors and engineers looking to improve the longevity and sustainability of their projects, fiberglass rebar mesh presents a compelling solution. Whether you’re building bridges, marine structures, or industrial facilities, fiberglass rebar mesh can help ensure that your construction projects stand the test of time. Consider exploring fiberglass rebar mesh for your next project and experience the benefits of this innovative material firsthand.