- October 23, 2024

- Posted by: wellcoindustries

- Category: Rebar

Introduction

As the construction industry evolves, the demand for stronger, more durable, and sustainable building materials has never been greater. One material that’s gaining significant attention is fiberglass rebar. This innovative alternative to traditional steel rebar is transforming the way infrastructure and construction projects are designed and executed.

Fiberglass rebar, made from a composite of glass fibers and resin, offers unique advantages over conventional steel reinforcement, particularly in environments where corrosion and harsh conditions are a concern. Its use is expanding rapidly in infrastructure projects such as bridges, tunnels, and marine structures, and it’s becoming a preferred option for engineers focused on sustainability and long-term durability. In this article, we’ll explore the many ways fiberglass rebar use is reshaping modern construction and why it’s a smart choice for a wide range of applications.

What is Fiberglass Rebar?

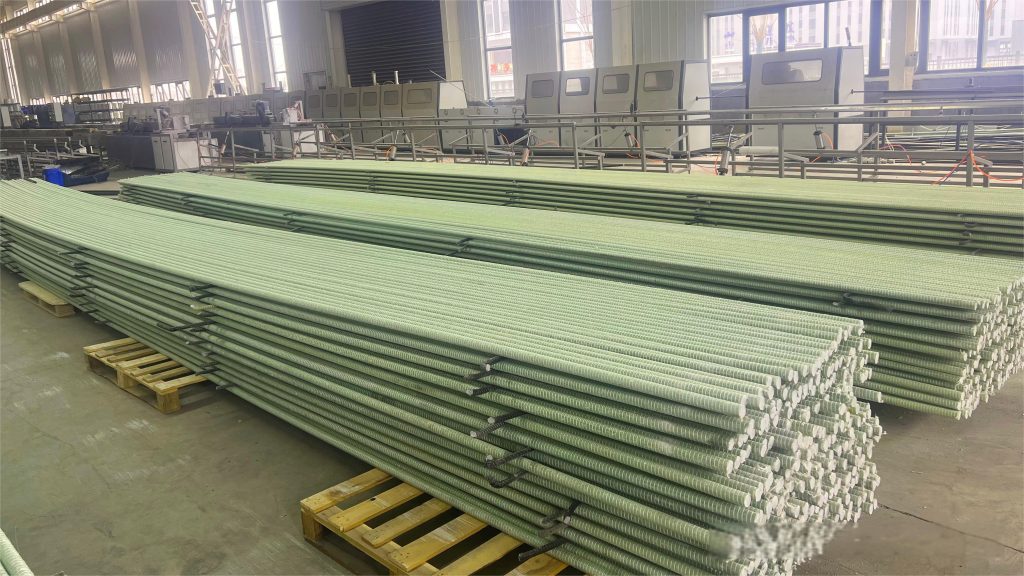

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, is a composite material made by combining glass fibers with a polymer resin. This results in a reinforcement material that is incredibly strong yet lightweight, offering a host of advantages over traditional steel rebar. Unlike steel, which is prone to corrosion when exposed to water, salt, and chemicals, fiberglass rebar is corrosion-resistant, making it particularly suitable for environments where such exposure is common.

One of the main reasons why fiberglass rebar is being adopted in place of steel is its ability to withstand harsh environmental conditions. For example, in marine construction, where steel rebar can degrade over time due to exposure to saltwater, fiberglass rebar remains unaffected, ensuring the longevity of the structure. Additionally, fiberglass rebar is non-conductive and non-magnetic, making it an ideal choice for projects where electromagnetic interference must be avoided, such as in medical or research facilities.

Moreover, when comparing fiberglass rebar vs. steel rebar, one of the most significant differences is the weight. Fiberglass rebar is about one-quarter the weight of steel, which not only makes transportation and handling easier but also reduces labor costs and installation time.

Key Benefits of Using Fiberglass Rebar

1. Corrosion Resistance: One of the most compelling advantages of using fiberglass rebar is its resistance to corrosion. This makes it particularly useful in construction projects exposed to moisture, salt, or chemical environments, such as coastal infrastructure or wastewater treatment plants. Where steel rebar would corrode over time, fiberglass rebar maintains its integrity, extending the lifespan of the structure and reducing maintenance costs.

2. Lightweight Yet Strong: Fiberglass rebar boasts an impressive strength-to-weight ratio, offering the same, if not greater, tensile strength as steel while being significantly lighter. This not only reduces the overall load on the structure but also simplifies transportation and handling during the construction process. Workers can move and install fiberglass rebar with greater ease, which in turn can speed up project timelines.

3. Durability in Harsh Environments: Fiberglass rebar is particularly advantageous in projects exposed to extreme environmental conditions. Whether it’s a bridge exposed to saltwater or a chemical plant where corrosive substances are a daily concern, fiberglass rebar stands up to these challenges better than steel. This durability makes it a long-term investment that can lower repair and replacement costs in the future.

4. Non-conductive and Non-magnetic: In certain applications, such as hospitals, laboratories, or buildings where magnetic fields could interfere with sensitive equipment, the non-conductive and non-magnetic properties of fiberglass rebar make it a safer and more reliable choice. This unique characteristic is an essential advantage over steel rebar, which can interfere with electromagnetic equipment and signals.

These key benefits are driving the adoption of fiberglass rebar in a wide range of projects where durability, longevity, and cost-effectiveness are critical.

Common Applications of Fiberglass Rebar

Fiberglass rebar is proving to be an excellent choice in various construction projects due to its unique properties. Here are some of the most common fiberglass rebar applications:

1. Infrastructure Projects: Fiberglass rebar is increasingly used in the construction of bridges, highways, and tunnels. These projects often face environmental stressors, such as moisture and salt, which can deteriorate steel rebar over time. In contrast, fiberglass rebar resists corrosion, providing a more durable solution that requires less maintenance, ultimately reducing costs.

2. Marine Construction: Structures like docks, seawalls, and piers are constantly exposed to the harsh marine environment, where saltwater can rapidly corrode steel rebar. Fiberglass rebar, with its corrosion-resistant properties, is ideal for these applications, ensuring the structures remain intact and stable for much longer.

3. Industrial Projects: Fiberglass rebar is also favored in chemical plants, where exposure to aggressive chemicals is a daily occurrence. In such environments, steel can corrode quickly, leading to structural weaknesses. Fiberglass rebar, on the other hand, maintains its strength and structural integrity even in the presence of harsh chemicals.

4. Residential Construction: In residential projects, fiberglass rebar is often used in foundations, driveways, and swimming pools, where its lightweight nature makes it easier to handle and install. Additionally, its resistance to corrosion means that these structures will last longer with fewer repairs, making fiberglass rebar a cost-effective choice for homeowners and builders alike.

Fiberglass Rebar in Sustainable and Green Construction

As the construction industry shifts towards more sustainable practices, the use of fiberglass rebar plays a significant role in promoting green building initiatives. Its long lifespan and minimal maintenance requirements contribute to the reduction of the overall carbon footprint of construction projects. Traditional steel rebar requires regular maintenance and replacements, which increases both material waste and energy consumption over time.

Furthermore, fiberglass rebar’s durability means fewer resources are needed to maintain and repair structures, reducing the environmental impact associated with continuous upkeep. In projects aimed at sustainable construction, choosing materials like fiberglass rebar that offer long-term benefits helps meet green building standards and certifications.

Cost and Availability Considerations

While the initial cost of fiberglass rebar can be higher than that of traditional steel rebar, the long-term savings make it a cost-effective investment. Fiberglass rebar’s ability to resist corrosion and require minimal maintenance significantly reduces long-term costs associated with repairs and replacements. For contractors and engineers looking to cut down on lifetime costs while ensuring the durability of their projects, fiberglass rebar presents a compelling option.

As more suppliers enter the market, fiberglass rebar availability has become widespread, making it accessible for a variety of construction projects globally. This increased availability is driving its adoption across multiple sectors, from industrial to residential applications.

Conclusion

Fiberglass rebar is transforming the construction industry by offering a superior alternative to traditional steel rebar. Its corrosion resistance, lightweight strength, and ability to withstand harsh environments make it the ideal material for a wide range of applications. From bridges and highways to marine and industrial structures, fiberglass rebar use is growing rapidly, driven by its long-term durability and cost-effectiveness.

As the industry continues to embrace sustainable and green building practices, fiberglass rebar’s role in reducing maintenance and extending the lifespan of structures positions it as a valuable asset in modern construction. If you’re considering materials for your next project, fiberglass rebar could be the key to ensuring long-term success and resilience.