- January 15, 2025

- Posted by: wellcoindustries

- Category: Rebar

Introduction

When planning your next construction project, the pros and cons of FRP rebar (Fiber-Reinforced Polymer rebar) are critical factors to consider. FRP rebar has emerged as an innovative alternative to traditional steel rebar thanks to its strong resistance to corrosion and potential to extend the lifespan of concrete structures. In this article, we’ll explore whether this material is truly the right choice for your upcoming project by examining its benefits, drawbacks, and key considerations.

Understanding FRP Rebar

What Is FRP Rebar

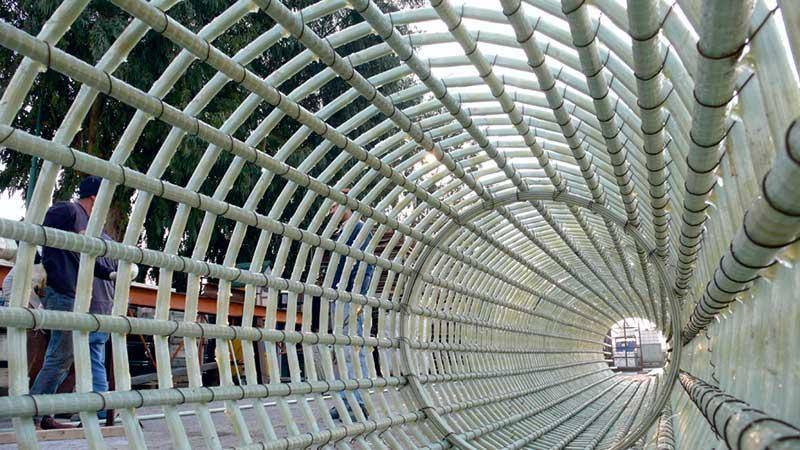

FRP rebar is made from a combination of polymer resin and reinforcing fibers—commonly fiberglass. Instead of relying on steel, engineers use these composite bars to reinforce concrete in structures such as bridges, parking garages, and marine facilities. The primary attraction is its ability to resist corrosion, which can be a major concern in harsh or high-moisture environments.

Why FRP Is Gaining Popularity

The construction industry is constantly looking for ways to reduce maintenance costs and extend the service life of structures. Steel rebar, while cost-effective initially, is susceptible to rust in salty or humid conditions, eventually compromising the integrity of a structure. By contrast, FRP rebar can withstand these elements for longer. According to a 2018 publication by the American Concrete Institute (ACI), advanced composites like FRP can lower overall lifecycle costs by reducing the frequency of repairs and replacements.

Pros of FRP Rebar

Corrosion Resistance

One of the biggest advantages is its immunity to corrosion. Steel rebar eventually rusts when exposed to moisture and chemicals like de-icing salts, leading to cracks and spalling in concrete. FRP rebar, on the other hand, is designed to resist these corrosive elements. This makes it an excellent choice for structures frequently exposed to water or harsh weather conditions—think coastal piers, water treatment facilities, or bridges that get salted during winter.

Lightweight and Easy Installation

FRP rebar weighs significantly less than steel—up to 75% less in some cases. This lightweight nature simplifies transportation and handling on the job site, reducing labor costs. Workers can move and install FRP bars more quickly, improving overall productivity. Additionally, due to the decreased risk of injury while handling lighter materials, job safety may also see a boost.

Lower Lifecycle Costs

Though initial costs can be higher (a point we will address in the cons), FRP rebar can end up saving money in the long run. Because it doesn’t corrode like steel, long-term maintenance expenses are significantly reduced. Over time, the cost of replacing or repairing damaged steel rebar can far exceed any initial savings from opting for conventional materials. Multiple studies note that FRP’s durability often makes it a smart investment for structures with long service requirements.

Cons of FRP Rebar

Higher Initial Cost

Despite its long-term benefits, FRP rebar is generally more expensive to purchase upfront compared to steel. This higher cost can be a deterrent for projects operating under a tight budget. Developers and contractors must evaluate whether the anticipated reduction in maintenance and repair expenses offsets the premium cost of FRP materials.

Limited Industry Familiarity

Although FRP has been around for several decades, it’s still less common than steel in many regions. This unfamiliarity can lead to design and construction challenges, as not all engineers and contractors are well-versed in FRP installation practices. In some cases, local building codes and standards may need special approval or require additional documentation to ensure compliance when using FRP.

Potential for Brittleness

FRP rebar does not yield (stretch) like steel, which can act as an early warning mechanism for structural failures. In situations where a structure undergoes high stress beyond its design limits, steel can bend to a certain degree, alerting engineers to potential problems. FRP’s rigidity may lead to a sudden failure if not engineered correctly. As a result, careful design calculations and safety factors are crucial to prevent unexpected fractures.

Key Considerations for Implementation

Project Type and Environment

FRP rebar can be highly advantageous for specific projects—particularly those in corrosive or marine environments. However, it might be less essential for structures in relatively dry or low-risk regions. Assessing environmental conditions and project demands will guide whether the benefits of FRP outweigh its additional costs.

Design and Engineering Constraints

When switching from steel to FRP rebar, project engineers must carefully adjust their calculations. FRP’s mechanical properties—such as tensile strength and modulus of elasticity—differ significantly from steel. This difference requires changes to spacing, cover, and overall structural design. Engaging engineers experienced with composite materials is crucial to ensure the design meets the necessary safety standards.

Supplier and Contractor Expertise

Choosing the right supplier and contractor is equally essential. Not all construction teams are familiar with handling FRP rebar, which can lead to incorrect installations if best practices are not followed. Work with reputable manufacturers who can provide certifications, testing results, and detailed installation guidelines. Additionally, ensure your contractor has prior FRP experience or is willing to collaborate closely with suppliers to learn proper procedures.

Conclusion

When weighing the pros and cons of FRP rebar, it’s clear that FRP offers several compelling benefits—primarily its corrosion resistance, lower overall maintenance costs, and ease of installation. On the flip side, higher initial costs, limited industry familiarity, and brittleness under extreme stress can pose challenges. Ultimately, the best decision hinges on your project’s budget, environment, and design requirements.

Whether you’re a developer, contractor, or engineer, understanding these factors will help you decide if FRP rebar is the right fit. If you found this article helpful, feel free to share it with your network or leave a comment below. Want more insights on advanced construction materials? Subscribe to our newsletter for the latest industry updates and expert tips.