- January 3, 2025

- Posted by: wellcoindustries

- Category: Rebar

Introduction

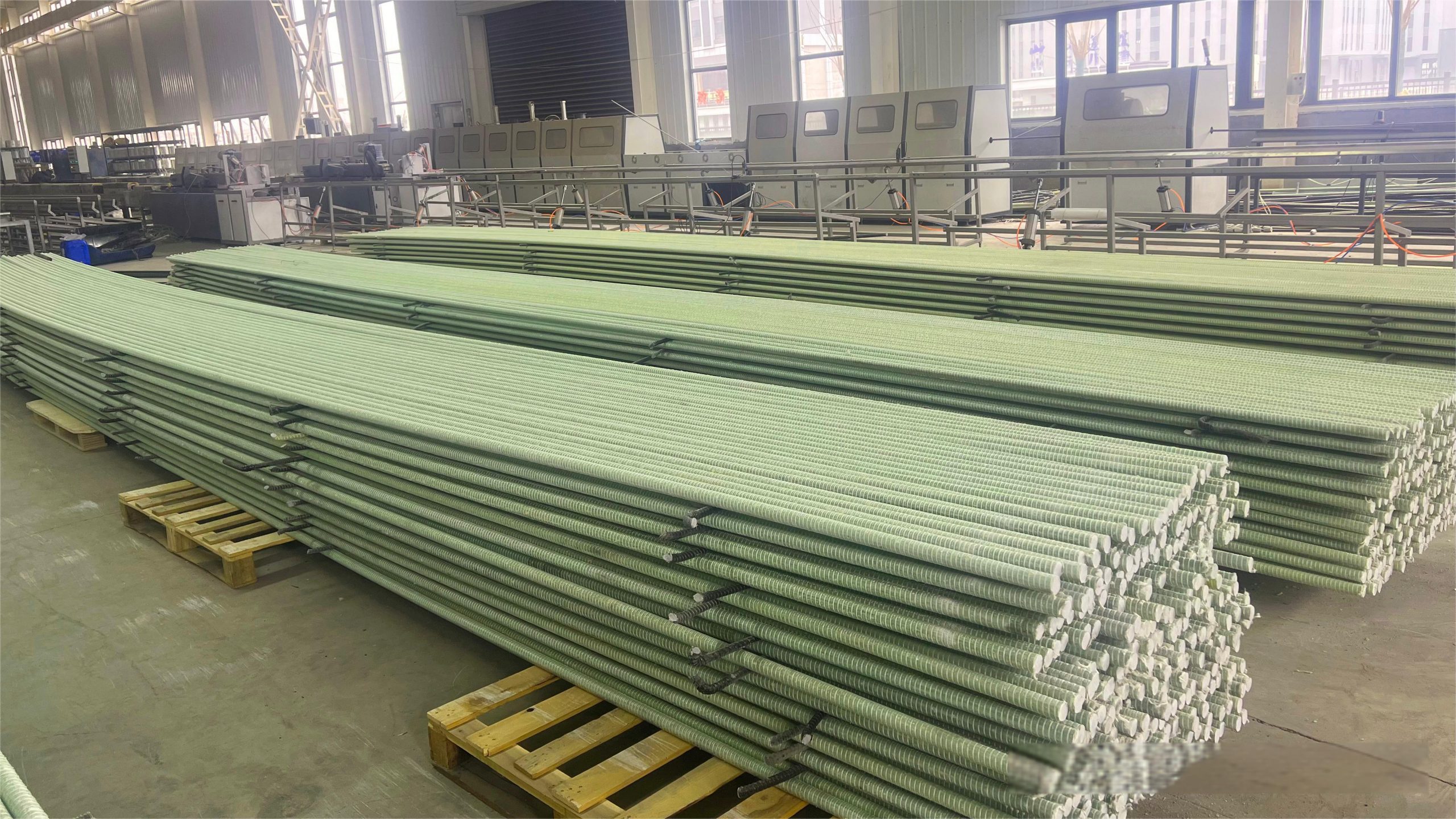

Fiber-reinforced polymer (FRP) rebar is revolutionizing the construction industry with its superior strength, lightweight nature, and resistance to corrosion. However, producing high-quality FRP rebar requires advanced technology, and this is where pultrusion lines come into play. These lines are essential for ensuring consistent, efficient, and reliable production. In this article, we’ll explore the top features to look for when selecting an FRP rebar pultrusion line, helping you make an informed investment.

What is an FRP Rebar Pultrusion Line?

An FRP rebar pultrusion line is a manufacturing system designed to produce FRP rebar through the pultrusion process. This involves pulling reinforced fibers through a resin bath and then shaping and curing them in heated dies. The result is a strong, lightweight, and durable rebar ideal for modern construction needs.

The pultrusion line ensures uniformity and high quality, making it a critical component for manufacturers aiming to meet stringent industry standards. Its efficiency directly impacts production speed, material consistency, and overall output quality.

Top Features of an Advanced FRP Rebar Pultrusion Line

High-Precision Control Systems

Precision is key in the pultrusion process. Advanced control systems allow for accurate management of temperature, resin application, and pulling speed. This ensures that the rebar produced has consistent strength, diameter, and surface finish. A pultrusion line equipped with cutting-edge sensors and control software minimizes errors and optimizes efficiency.

Robust and Durable Equipment

A high-quality pultrusion line should be built with durable materials to withstand continuous operation. The equipment must resist wear and tear, ensuring minimal maintenance and downtime. Look for lines with components made from corrosion-resistant alloys and reinforced frames for longevity and reliability.

Automated Resin Application and Curing

Automation is a hallmark of modern pultrusion lines. Automated resin application ensures uniform coverage, reducing waste and improving product quality. Additionally, precise curing processes controlled by advanced heating systems speed up production while maintaining structural integrity.

Versatile Design Capabilities

Construction projects often require FRP rebar in various sizes and specifications. A versatile pultrusion line allows manufacturers to easily switch between different molds and settings, accommodating diverse production needs. This flexibility enhances competitiveness in the market.

Energy Efficiency and Environmental Considerations

Energy efficiency is not just a cost-saving measure; it’s a commitment to sustainability. Advanced pultrusion lines incorporate energy-saving features such as insulated curing systems and optimized power consumption. Furthermore, environmentally friendly designs reduce emissions and waste, aligning with green manufacturing standards.

Benefits of Investing in a Quality Pultrusion Line

Choosing a top-tier FRP rebar pultrusion line offers several advantages:

- Enhanced Productivity: Advanced systems reduce downtime and accelerate production.

- Consistent Quality: High-precision controls ensure uniformity and meet industry standards.

- Cost Savings: Durable equipment and efficient processes lower operational costs over time.

- Market Competitiveness: Versatile lines enable manufacturers to cater to diverse customer needs.

Conclusion

Investing in the right FRP rebar pultrusion line is a crucial step for manufacturers aiming to deliver top-quality products while maintaining cost efficiency. By prioritizing features such as high-precision controls, durability, automation, versatility, and energy efficiency, you can ensure optimal production outcomes.

Ready to take the next step? Consult with industry experts or explore trusted manufacturers to find a pultrusion line tailored to your needs. Your investment today can set the foundation for long-term success in the competitive construction materials market.