- December 25, 2024

- Posted by: wellcoindustries

- Category: Rebar

Introduction

Fiber Reinforced Polymer (FRP) rebar has emerged as a game-changing material in modern construction, offering an innovative alternative to traditional steel rebar. Renowned for its unique mechanical properties, FRP rebar provides solutions to long-standing challenges such as corrosion and heavy weight. This article delves into the mechanical properties that make FRP rebar a standout choice for infrastructure, industrial, and commercial projects, explaining its strength, durability, and application benefits.

What Is FRP Rebar?

Composition of FRP Rebar

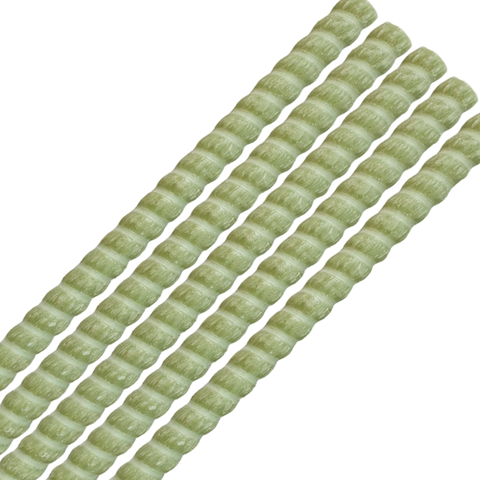

FRP rebar is a composite material composed of high-strength fibers (such as glass, carbon, or basalt) embedded in a polymer matrix. The combination creates a lightweight yet durable material. The fibers contribute to the rebar’s tensile strength, while the polymer matrix offers resistance to environmental degradation.

How FRP Rebar Differs from Steel Rebar

Unlike steel, FRP rebar is non-metallic, making it immune to corrosion—a common issue in steel-reinforced structures. Additionally, FRP rebar is significantly lighter, simplifying transportation and installation. These differences give FRP rebar a clear advantage in environments where durability and weight reduction are priorities.

Key Mechanical Properties of FRP Rebar

Tensile Strength

FRP rebar exhibits exceptional tensile strength, often surpassing that of steel. This makes it ideal for structures exposed to high tension, such as bridges and marine structures. The higher strength-to-weight ratio reduces material requirements without compromising performance.

Elastic Modulus

The elastic modulus of FRP rebar is lower than steel, which means it is less stiff. While this flexibility can be a limitation in some designs, it allows for greater energy absorption in certain applications, such as earthquake-resistant structures.

Shear Strength

FRP rebar has sufficient shear strength to withstand lateral forces. This property is particularly critical in areas prone to seismic activity or heavy vehicle loads, ensuring structural stability.

Fatigue Resistance

FRP rebar offers superior fatigue resistance, maintaining its structural integrity under repeated stress over time. This makes it an excellent choice for projects requiring long-term durability, such as industrial plants and high-traffic bridges.

Advantages of FRP Rebar in Construction

Corrosion Resistance

One of the most significant benefits of FRP rebar is its resistance to corrosion, even in harsh environments like marine or chemical settings. Unlike steel, it does not rust, ensuring a longer lifespan for structures.

Lightweight and High Strength-to-Weight Ratio

FRP rebar is much lighter than steel, simplifying transportation and installation. This property also reduces the overall weight of structures, making it suitable for projects where weight reduction is critical.

Longevity and Low Maintenance Costs

While the initial cost of FRP rebar may be higher than steel, its resistance to corrosion and fatigue results in lower maintenance costs over the lifecycle of the structure. This makes it a cost-effective solution in the long run.

Challenges and Limitations of FRP Rebar

Initial Cost Considerations

The upfront cost of FRP rebar is typically higher than steel. However, its extended durability and reduced maintenance expenses often offset this initial investment.

Compatibility with Existing Construction Standards

Because FRP rebar behaves differently than steel, engineers may need to adapt their designs to accommodate its unique properties. This can involve adjustments to traditional design codes and practices.

Temperature Sensitivity

Extreme temperatures can affect the performance of FRP rebar, particularly its polymer matrix. It’s essential to consider temperature ranges in the project’s location during material selection.

Applications of FRP Rebar

Infrastructure Projects

FRP rebar is extensively used in infrastructure projects such as bridges, highways, and seawalls. Its corrosion resistance and lightweight properties are crucial in these demanding environments.

Industrial and Chemical Plants

In environments with exposure to chemicals or high levels of moisture, FRP rebar provides unparalleled resistance to degradation, ensuring the longevity of industrial facilities.

Residential and Commercial Construction

While more common in large-scale projects, FRP rebar is also gaining popularity in residential and commercial applications, offering benefits in durability and ease of construction.

Conclusion

FRP rebar’s mechanical properties—tensile strength, elasticity, shear strength, and fatigue resistance—make it a versatile and valuable material for modern construction. Its advantages in durability, corrosion resistance, and low maintenance costs position it as a superior alternative to traditional steel rebar. As infrastructure demands evolve, FRP rebar stands out as a material that can meet the challenges of the future.

Call to Action: Are you ready to explore the benefits of FRP rebar for your next project? Contact us today to learn how this innovative material can transform your construction approach!